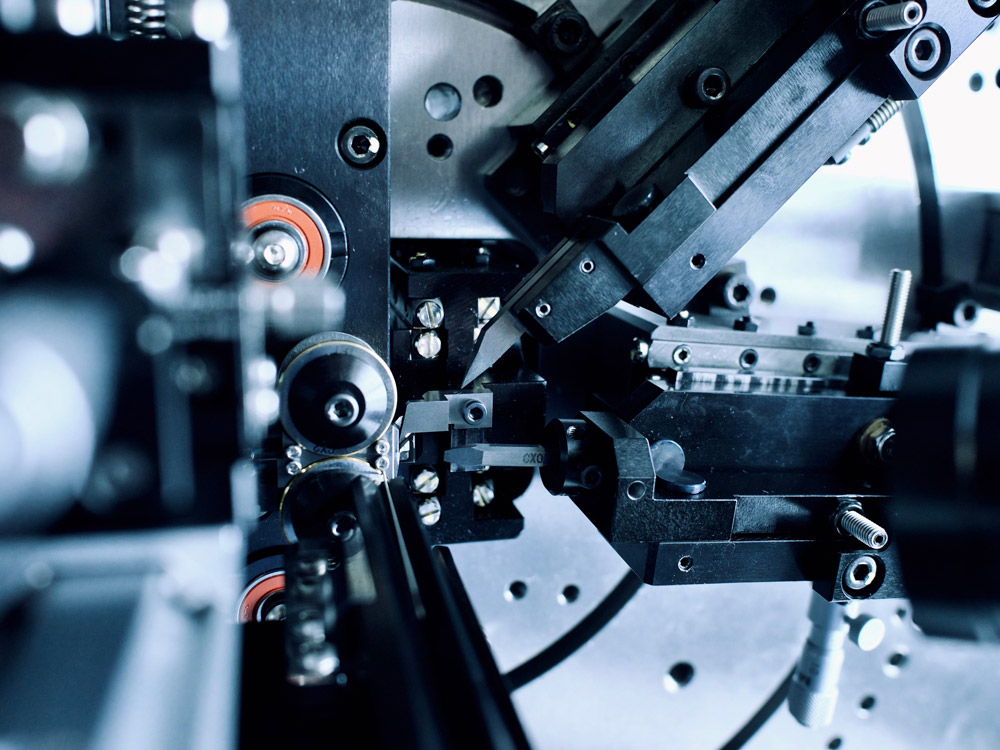

Shannon Coiled Springs today commissioned its new ITAYA EUROPE CX2 Micro Coiler, further extending the company’s capabilities in ultra-fine spring manufacture. Designed for wire diameters down to 0.05 mm, the CX2 brings precision micro-coiling into SCS’s ISO 13485-certified white-room environment, enabling more complex geometries for medical, aerospace and high-tech applications.

The addition of the CX2 reinforces SCS’s collaborative engineering approach. Its multi-axis, computer-controlled feed and cut system ensures consistent accuracy, while on-board programming and USB memory support rapid prototyping and seamless changeovers. This investment dovetails with SCS’s existing micro-coiling expertise, allowing customers to move from concept through validation to production without compromising on tolerance or turnaround.

By integrating the CX2 into its production line, Shannon Coiled Springs strengthens its position as a dependable partner for mission-critical spring solutions. Customers benefit from shorter development cycles, tighter quality control at the micro scale and streamlined scale-up for regulated programmes.

Key highlights:

- Ultra-fine wire coiling from 0.05 mm with repeatable accuracy

- Computer-driven multi-axis control for complex spring geometries

- On-board programming and USB memory for faster prototyping and production

- Seamless integration with ISO 13485-certified white-room and quality systems